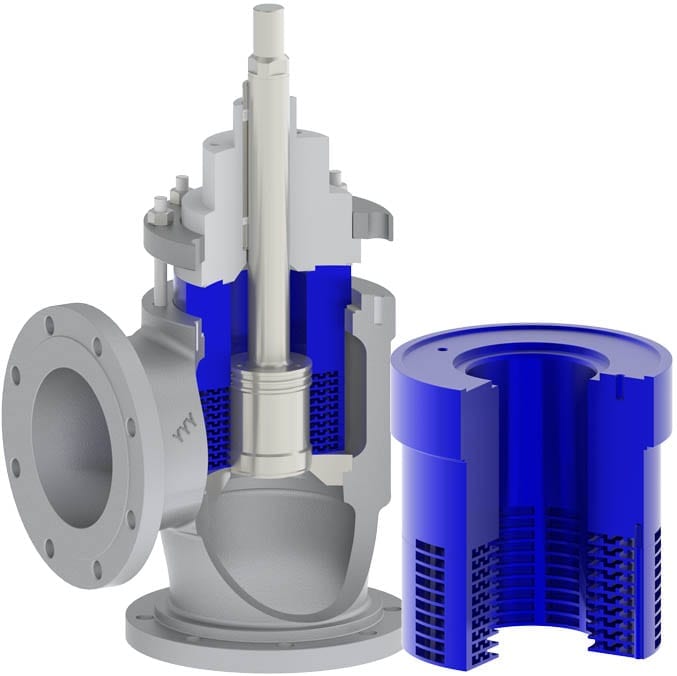

ST-4 Stacked Disc trim is a powerful solution designed to tackle the most severe pressure drops while reducing sound levels and eliminating the effects of cavitation. It can be used in liquid, gas, or dual-phase service. The ST-4 design consists of individual discs machined with concentric channels machined to create a tortuous path and stacked to create a compact cylinder. The cylinder is then clamped into the body cavity of an OpGL globe valve and doubles as a seat retainer.

Flow in this case is under the plug and as the fluid travels from the interior of the cylinder through either jagged grooves, through whcih it is forced to make a series of 45-degree dives and ascents, or through 90-degree labyrinthine turns. Simultaneously, the size of the channels increases allowing for expansion and thus reducing the pressure in stages.

- Tolerates Sigma as low as 1.001

- Can be characterized

- Noise abatement of up to 30dBA

- Custom-engineered for optimization and characterization of flow according to application requirements – including dirty service

Print

Print