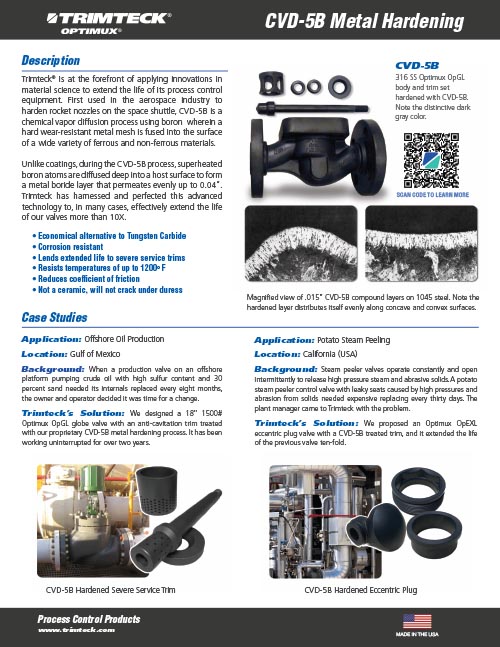

Trimteck is at the forefront of applying innovations in material science to extend the life of process control equipment. First used in the aerospace industry, CVD-5B is a chemical vapor diffusion process wherein a hard wear-resistant metal mesh is fused into the surface of a wide variety of ferrous and non-ferrous materials. Trimteck has harnessed and perfected this advanced hardening technology to – in some cases – effectively extend the life of our valves 10-fold.

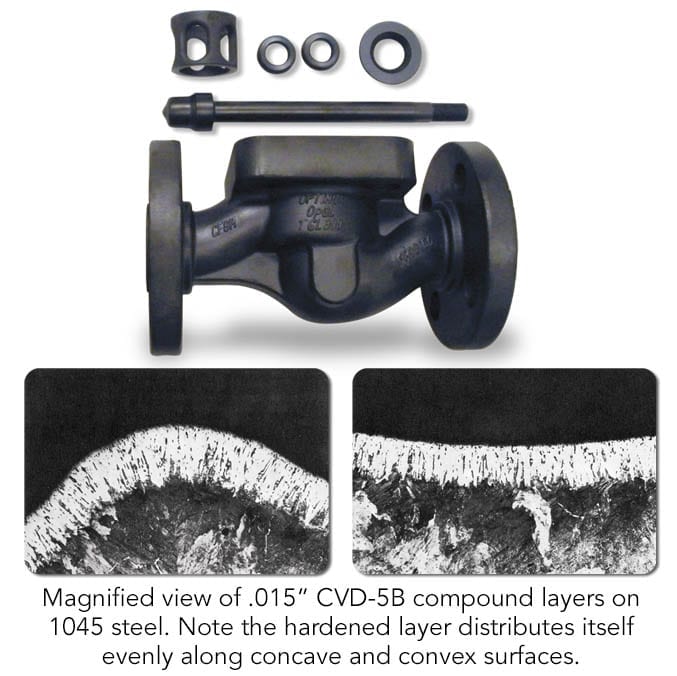

Industrial customers have increasingly demanded that process control equipment also be wear-resistant and capable of sustaining higher temperatures, and CVD-5B was developed as a cost-effective alternative for addressing these process control issues. Unlike coatings and traditional hard facings that harden only the surface of the substrate material, during the CVD-5B hardening process, superheated boron atoms are diffused fairly deep into a host surface to form a metal boride layer that permeates evenly up to .015’’.

- Economical alternative to Tungsten Carbide

- Corrosion resistant; acids and bases

- Lends extended life to severe service trims

- Resists temperatures of up to 1200o F

- Reduces coefficient of friction

- Not a ceramic, will not crack under duress

Note: In addition to our proprietary CVD-5B Hardening, Trimteck also offers traditional hardened trim materials, such as:

- Tungsten Carbide

- Stellite

- Nickel

- Hard Chrome

- Titanium

- Zirconium

Print

Print