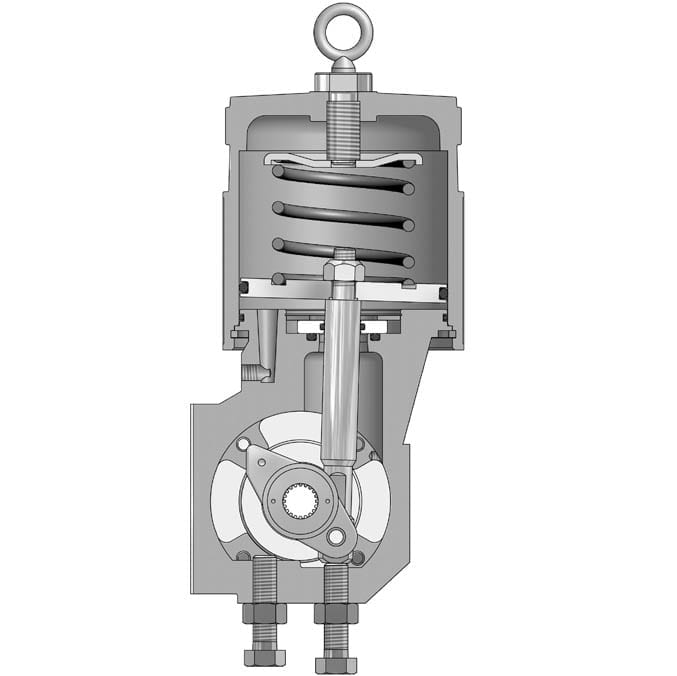

The Trimteck OpTK Rotary Piston-Cylinder Actuator combines high torque and pneumatic stiffness with excellent throttling capabilities. These characteristics are designed into a lightweight, rugged and compact assembly.

The actuator and cylinder are designed for supply pressures up to 150 psi, enabling very high torques. The actuator uses a rocking piston for direct conversion of linear motion to rotary motion – thrust to torque. The rocking piston assembly combined with a splined shaft and lever eliminates lost motion giving the OpTK extraordinary precision and resolution.

Accepts up to 150 psi air supply

- Achieves higher torques

- Obtains stiff piston positioning

- Permits higher DP limits on valve

Rocking piston

- Provides direct connection to shaft

- Assures zero lost motion between actuator and valve

- Utilizes fewer parts

Splined shaft and lever

- Allows zero lost motion

Compact, lightweight, rugged

- Permits easy maintenance

- Installs in limited space applications

- Easily meets seismic requirements

Low friction bearings

- Provide millions of cycles with minimal wear

- Combined with direct linkage, provides very low hysteresis

Field reversible

- Requires no extra parts

- Permits fast, easy field reversing

- Requires no change of spring action

Fail-safe spring

- Moves actuator to failure position without pressure assistance

Air-purged, fully enclosed transfer case

- Prevents corrosion of linkage

- Ensures safe operation

- Contains external position indicator

- Allows four mounting positions without retubing, changing or adding parts

Stroke stops

- Allow both ends of stroke to be adjusted

Print

Print