Introduction to Actuators.

With most control valves, some mechanical device or external system must be devised to open or close the valve, or to change the position of the valve if it is to be used in throttling service.

Automatic control of valves requires an actuator, which is defined as any device mounted on a valve that, in response to a signal, automatically moves the valve to the required position using an outside power source.

Trimteck manufactures a comprehensive line of Optimux globe control valves – and a variety of actuators, positioners, severe service trims and other accessories – that our applications engineers and representatives use to solve the most complex flow, pressure, and temperature control challenges quickly and economically.

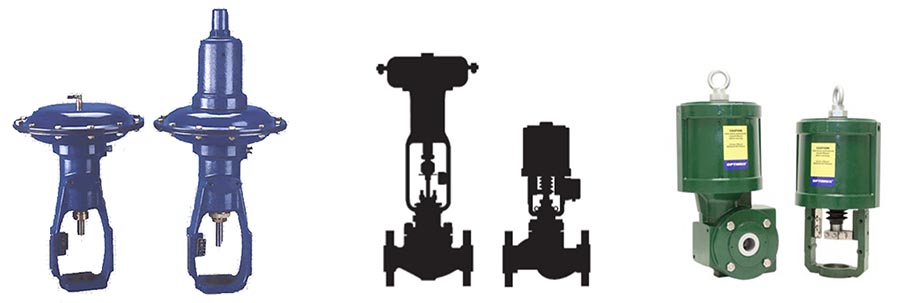

Trimteck Actuators

Featured Actuator Solutions

At Trimteck, we are obsessed with quality.

Browse from our selection of engineered Actuator solutions for your applications below. Click a product to read full details and documentation.

-

Actuators

OpTK™ Linear Piston-Cylinder Actuator

-

Actuators

OpTK™ Rotary Piston-Cylinder Actuator

-

Actuators

OpSY™ Scotch Yoke Type Actuator

Trimteck Actuator

Solution Information

How do we classify types of Actuators ?

There are two basic classifications for process control application:

1

Pneumatic Actuators

- Diaphragm

- Piston-Cylinder

- Rack and Pinion

- Rack and Gear

- Scotch Yoke

2

Non-Pneumatic Actuators

- Electromechanical

- Electro Hydraulic

- Hydraulic

Diaphragm Actuator

Advantages

- Relatively inexpensive to produce

- Suited to low-pressure ranges where limited thrust is adequate

- Quick response

- Simple design

Disadvantages

- Height and weight

- Limited stroke

- Low thrust

- Pressure limitations on diaphragm

- Do not provide exceptional stiffness

- Not enough power to prevent “bathtub stopper effect”

- Not field-reversible, laborious maintenance

Note: Trimteck does not manufacture or market diaphragm actuators

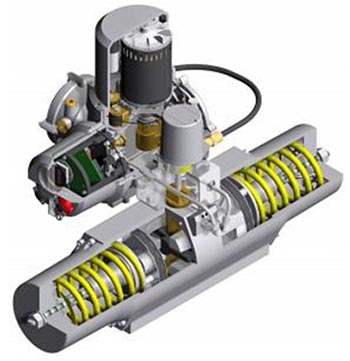

Piston-Cylinder Actuator (OpTK)

Advantages

- Higher thrust capability

- Compact and lightweight

- Faster stroking speed

- Longer stroke

- Greater stiffness prevents “bathtub stopper effect”

- Better performance than diaphragm actuators, with virtually no hysteresis, highly accurate signal response, and excellent linearity

- Field-reversible

Disadvantages

- Some breakout torque required

- Positioner adds to cost and complexity

Diaphragm vs. Piston Cylinder Thrust Comparison

[table id=5 /]

Conclusion: A far larger diaphragm actuator would be needed to provide the same thrust requirement as the piston cylinder actuator.

Rack and Pinion Actuator (OpRPA)

Advantages

- Suitable for both on/off and modulating control applications

- Durability and long cycle life

- Cost effective

- Versatility of casing materials

- Field-reversible

Misconceptions

- Only for on/off service

- Meets requirements for modulating control valves - Mechanical backlash

- Lash between racks and pinion is minimal, and shaft to control element has no lash; clamping device ensures no play between actuator pinion and valve shaft

Rack and Gear Actuator (OpRGA)

Advantages

- Offset pistons eliminate internal cantilever loads

- Low friction

- Exceptional throttling control capability

- Rugged

- Field reversible

- High cycle-life

- Stainless steel standard

- High temperature

- Low pressure options

- High speed option

- Easy installation and maintenance

Heavy Duty Scotch Yoke Actuator (OpSY)

Advantages

- Ideal for heavy-duty applications, particularly for ESD

- Excellent option for large valves with high breakout torque requirements

- Simple and infrequent maintenance requirements

- Known to achieve 1M cycles

- Pressure ranges from 40psi to 2500psi

- Torque from 1000in-lbs to 17,000in-lbs

Electromechanical

Advantages

- High degree of stability

- Constant thrust

- Extraordinary stiffness

- Fails in place upon loss of electric power

- Great solution for remote, solar-powered applications

Disadvantages

- Higher cost than pneumatic actuators

- Complexity

- Not recommended for flammable atmospheres

- Slower speeds

- Generate heat

Hydraulic and Electrohydraulic

Advantages

- Exceptionally stiff due to incompressibility of liquids

- Used in valves with low rangeability

- Fast stroking speeds

- Ideal for safety management systems

Disadvantages

- Expensive

- Large and bulky

- Complex

- Require specialized engineering

Actuator Performance Terminology

- Dead band – the maximum amount of input that is required to create a reversal in the movement of the actuator stem

- Frequency response – a response to a system or device to a constant-amplitude sinusoidal input signal

- Hysteresis – a common term used to describe the amount of position error that occurs when the same position is approached from opposite directions

- Independent linearity – the maximum amount that an actuator stem will deviate from a true straight linear line

- Maximum flow capacity – the volume of air pressure that can flow into an actuator during a particular time period measured in SCFM

- Open-loop gain – the ratio of the imbalance that occurs when an instrument signal change is made and the actuator stem is locked up

- Repeatability – similar to hysteresis, although it records the maximum variation of position when the same position is approached from the same direction

- Resolution – the smallest change possible in a valve- stem position

- Response level – the maximum amount of input change required to create a change in valve-stem position (in one direction only)

- Steady-state air consumption – applies to actuators with positioners in which the positioner consumes a certain amount of air pressure to maintain a required position

- Stiffness – the ability to hold a position despite process forces

- Stroking speed – the amount of time, in seconds, that an actuator requires to move from the fully retracted to the fully extended position

- Supply-pressure effect – the change of the actuator stem’s position for a 10-psi (0.7-bar) pressure change in the supply

More Information

Read our full documentation on Control Valves and Actuators.

What differentiates Trimteck from other manufacturers?

Organizational Differentiators

- Fast/Responsive

- Agile

- Consultative Quoting

- Control Valve Experts

- Experienced

- Robust & Modern Manufacturing Capabilities

- Made in USA

- Engineering Expertise

– Applications

– Design

– Simulation

Product Differentiators

- Reliable

- Robust

- Better/More Precise Control

- Broad Products/Solutions Portfolio

- Specific Technical Attributes for the range of service conditions:

– General

– Special

– Severe

PROUDLY SERVING OUR CUSTOMERS WORLDWIDE

Control Valves

How to order Control Valves for Severe Service from Trimteck

This website provides thorough coverage to assist customers in making informed choices for their facility's process control requirements.

If you need help don't hesitate to reach out to us. Thank you for your interest in our products!

2

Contact Trimteck

- Use our Find a Rep to locate a Trimteck authorized distributor

- Or contact Trimteck to speak with a sales engineer 954-753-5545

- Email us:

[email protected]

[email protected]

[email protected]

3

Submit your specifications

- Utilize our full Online Valve Specification Form

- Or request access to our Accuvalve Valve Sizing Specification software

Support Center

Did you find what you're looking for?

Aftermarket Service

Submit a request for

Parts and/or Service