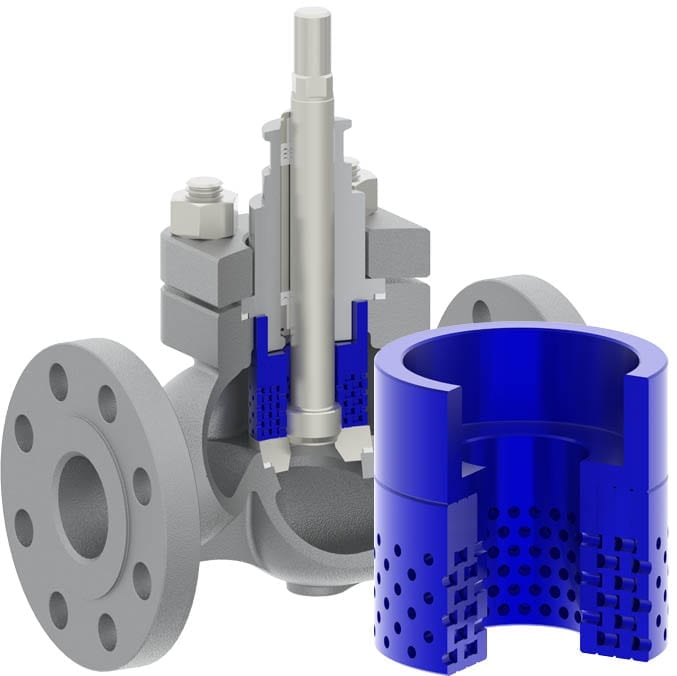

OpGL™ Cryogenic Globe Control Valve

Optimux OpGL Cryogenic Globe Control Valves are a low temperature variation of Trimteck’s flagship OpGL Globe Control Valve. The OpGL Cryogenic Globe Control Valve has been engineered to provide superior performance while permitting easy, fast, and inexpensive maintenance. Unlike diaphragm-operated control valves, the Piston cylinder-actuated OpGL™ provides stiffness and maintains high positioning accuracy – making for the world’s most efficient and accurately responsive valve.

To endure cryogenic temperatures as low as -420F, the OpGL Cryogenic Globe Control Valve can be configured with extended bonnets of various sizes, as well as special materials suited to cryogenic temperatures and applications, such as: 316SS, Monel, Nitronic 60, PCTFE, and others.

- Precise Control Broad range of control through a top-guided, unbalanced, single-piece plug with flow characterization built in to the geometry of the plug head.

- Exceptional Shutoff Standard ANSI Class V metal-to-metal shutoff in process achieved with unique plug and seat ring design. ANSI Class VI available in soft seated configuration.

- High Thrust Piston Actuator More accurate and quicker than diaphragm actuators, and offering a smaller and lighter footprint – ideal for skid-mounted process equipment.

- Maintainability Top-entry design facilitates maintenance, even though the valve has a much longer MTBS Cycle than competing diaphragm-actuated valves.

- Range of Trim Configurations From micro-flows to full capacity trims, and everything in between, the OpGL can be sized to optimally control according to your specific process parameters. A full line of anti-cavitation and noise abatement trims available.

Specifications

| Type (Groups) | Globe Valve, Linear Motion Cryogenic |

|---|---|

| Sizes (NPS) | 1/2", 3/4", 1", 1 1/2", 2", 3", 4", 6", 8", 10", 12", 14″, 16″, 18″, 20″, 24″ |

| Body Styles | Globe |

| Body Materials | Stainless Steel, Monel, Others |

| Pressure Class (ASME/ANSI) | CL150, CL300, CL600, CL900, CL1500, CL2500, CL4500 |

| Shutoff Class (ANSI) | Class IV, Class V, Class VI |

| End Connections | RF Integral Flange, NPT, RTJ, Buttweld, Socketweld, Grayloc, Others |

| Service | Special: High Pressure, Low Temperature, Low Flow, Corrosive, Erosive, Dirty, Zero Fugitive Emmissions, Severe: Cavitation, Noise, Flashing, General, Low Flow, Corrosive, Erosive, Dirty, Zero Fugitive Emissions, Cavitation, Noise, Flashing |

| Operating Temperature | Down to -420F |

| Flow Characteristic | Equal Percentage, Linear, Bi-Linear, Quick Open, Custom |

| Industries | Aerospace & Defense, Chemical/Petrochemical, Food & Beverage, Industrial Gases, Metals & Mining, Oil & Gas, Power, Pulp & Paper, Refining |

| Certifications/Norms | ANSI/ISA, ASME, CRN, NACE, PED |