Food & Beverage processing plants – distillers, refiners, brewers, millers, bakers, etc. – all have their own distinct flow, pressure, and temperature control challenges; but what they have in common is the need for predictability and operational efficiency. Undetected leaks, inconsistent mixtures, and unnecessary overflows can all impact product quality and increase plant maintenance costs.

Trimteck works with many of the world’s most demanding Food & Beverage companies to create innovative control valve solutions that contribute to lowering plant operating costs and increasing product predictability.

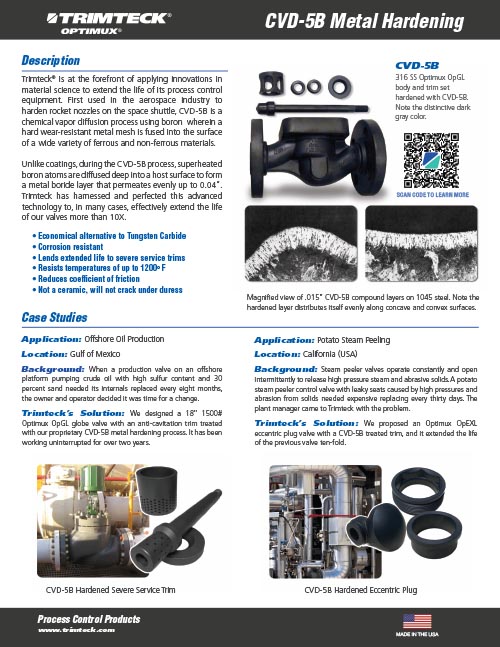

For instance, to counteract the abrasive effects of slurry and mash handling, we deploy our CVD-5B Metal Hardening process on the trim – and often the body – of the affected valve to increase its useful life up to ten-fold; and our OpEXL Eccentric Plug Rotary Control Valve has a frictionless seating design to further reduce the erosive effect of solids in suspension. Trimteck’s OpGL Globe Control Valves are ideal for steam and water handling/conditioning applications at pressures up to ANSI Class 4500.

Food & Beverage

Applications

There are myriad applications for Food and Beverage process control, however, most non-sanitary-grade applications can be divided into two categories: steam/water control and slurry/mash control. Trimteck’s OpGL Globe Control Valves are ideal for steam and water handling/conditioning applications. To counteract the abrasive effects of slurry and mash handling, we deploy our CVD-5B Metal Hardening process on the trim – and often the body – of the affected valve to increase its useful life up to ten-fold; and our OpEXL Eccentric Plug Rotary Control Valve has a frictionless seating design to further reduce the erosive effect of solids in suspension.

We build a comprehensive line of control valves – and variety of actuators, positioners, severe service trims, and other accessories – that our applications engineers and representatives use to solve even the most complex process control problems quickly and economically.

FEATURED LITERATURE

Let Trimteck help you develop solutions for your Food & Beverage applications.

Reactor Temperature Control

Boiler Feedwater

Flash Steam Peeling

Blowdown

Forced Convection Blanching

Poultry Processing

Level Control

Slurry/Mash Flow Control

PROUDLY SERVING OUR FOOD AND BEVERAGE CUSTOMERS

Food & Beverage

Featured Products

Support Center

Did you find what you're looking for?

Aftermarket Service

Submit a request for

Parts and/or Service